V Ring

Price 1 INR/ Piece

V Ring Specification

- Type

- V Ring

- Material

- Rubber

- Capacity

- Standard

- Computerized

- No

- Automatic Grade

- Manual

- Cutting Thickness

- Customizable as per requirement

- Belt Diameter

- Various sizes available

- Size

- Standard and customized

- Width

- As per specification

- Weight

- Lightweight

- Dimension (L*W*H)

- Standard/Custom

- Hardness

- 6080 Shore A

- Application

- Shaft sealing; Excludes dust, water and oil

- Shape

- V-Shaped Ring

- Seal Type

- Axial seal for rotary shafts

- Temperature Resistance

- -30C to 200C

- Installation

- Easy slip-on design

- Feature

- Resistant to wear, chemical and ozone

- Tensile Strength

- High

- Elastomer Type

- Nitrile (NBR), EPDM, Viton (FKM), or customized

- Color

- Black or as required

V Ring Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About V Ring

The V Ring that presented by us is utilized as a pressure-less seal in order to prevent water, oil, dirt, dust, and splash to enter the system. Such ring is ideal for applications for agricultural machines, pumps, rolling mils, electro motors, paper machines, and metal & wood treatment devices. This is made of top-grade rubber with cutting-edge molding technology to ensure its ideal shape & size with smooth edges finish. Moreover, the V Ring can be availed in required quantity with A-one packaging.

Exceptional Performance in Shaft Sealing

Designed to efficiently protect against dust, water, and oil, the V Ring ensures reliable shaft sealing. Its robust composition, utilizing elastomers such as NBR, EPDM, and FKM, enables a broad operational temperature range and excellent resistance against harsh environmental conditions. This seal provides long-lasting performance in both standard and custom dimensions.

Versatile Applications and Customization

Suitable for a wide array of industries, the V Ring seals are available in standard and customized versions to accommodate different shaft sizes and operating conditions. The easy slip-on design simplifies installation, making it suitable for use in both new and retrofitted machinery. Color, width, weight, and other dimensions can be customized to meet specific operational needs.

FAQs of V Ring:

Q: How is the V Ring installed on a rotary shaft?

A: The V Ring features an easy slip-on design, allowing it to be manually fitted onto the shaft without the need for special tools. Its flexibility ensures a secure and precise axial seal, simplifying installation and maintenance.Q: What types of elastomer materials are available for these V Rings?

A: Our V Rings are offered in high-quality rubber materials such as Nitrile (NBR), EPDM, and Viton (FKM). Customized elastomer options can also be provided to match unique application requirements.Q: When should I use a V Ring for shaft sealing?

A: A V Ring is recommended whenever you need to exclude contaminants like dust, water, or oil from entering machinery via rotating shafts, especially under conditions involving chemical exposure, temperature extremes, or mechanical wear.Q: Where are V Rings typically utilized?

A: V Rings are widely used across sectors such as automotive, industrial machinery, pumps, electric motors, and agricultural equipment, wherever effective sealing of rotary shafts is critical.Q: What is the benefit of choosing a V Ring with customizable dimensions?

A: Customizable dimensions ensure a perfect fit for your specific application, enhancing sealing efficiency, prolonging component life, and supporting optimal machine performance.Q: How does the V Rings temperature resistance benefit its application?

A: With a temperature tolerance from -30C to 200C, the V Ring maintains its sealing performance in both extreme cold and hot environments, making it versatile for diverse operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Breweries Distillery Machine Spares Category

Gripper Pusher Unit

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Highgrade Alloy Steel with Engineered Polymer Parts

Automatic Grade : SemiAutomatic

Size : Standard/Customizable

Capacity : Suitable for MediumtoHeavy Duty Industrial Applications

Crowner Pad - Bottle Seat

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Premium PU Foam

Automatic Grade : Manual

Size : Standard Bottle Size Fit

Capacity : Single Bottle Support

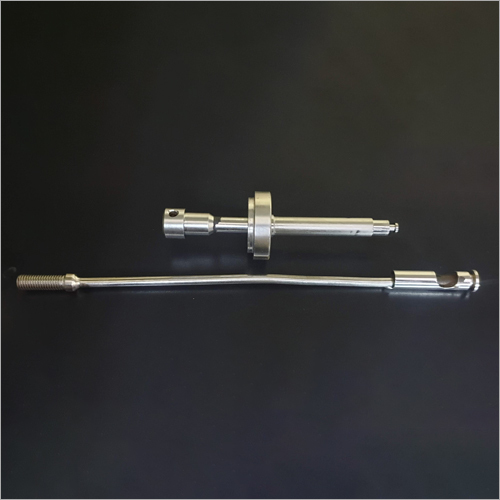

Cardan Shaft

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Alloy Steel

Automatic Grade : Manual

Size : As per requirement

Capacity : High torque transmission

Filling Nozzle

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Automatic Grade : Manual

Size : Standard/Custom sizes available

Capacity : Customizable as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free