Cardan Shaft

Price 1 INR/ Piece

Cardan Shaft Specification

- Type

- Cardan Shaft

- Material

- Alloy Steel

- Capacity

- High torque transmission

- Computerized

- No

- Automatic Grade

- Manual

- Size

- As per requirement

- Width

- Customizable

- Weight

- Varies with specification

- Dimension (L*W*H)

- Custom as per application

- Joint Type

- Universal joints

- Shaft Diameters Available

- From 40 mm to 400 mm

- OEM Service

- Available

- Max RPM

- Up to 6000 RPM

- Features

- High speed, high torque, easy installation, maintenance free

- Corrosion Resistance

- Yes

- Model Number

- Custom order

- Surface Treatment

- Phosphated and powder coated

- Operating Temperature

- -20°C to +80°C

- Application

- Used in industrial machines, rolling mills, paper machines, textile machines

Cardan Shaft Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Cardan Shaft

With valuable assistance of well-experienced and dedicated team members, we are keenly engrossed in bringing forth the best-in-grade Cardan Shaft. The shaft that we present is most widely utilized as an element of mechanical power transmission in a variety of heavy industrial machines like Paper Machines, Pumps, Marine drives, etc. The Cardan Shaft is well fabricated from top-of-the-line metal and coating material with leading-edge casting technique under the guidance of adept professionals that ensures it high durability, ideal dimension, and low maintenance cost.

Superior Performance Across Industries

Designed for demanding applications, our Cardan Shafts deliver high torque transmission and stand up to rigorous use in rolling mills, paper machines, and textile manufacturing. Their wide operating temperature range and top-tier corrosion resistance make them reliable for heavy-duty industrial environments.

Precision Engineering and Flexibility

Each shaft can be fully customized to your specific requirementswhether related to size, capacity, or unique installation constraints. Extensive surface treatments extend product longevity, and the universal joint design ensures smooth and durable operation at speeds up to 6000 RPM.

FAQs of Cardan Shaft:

Q: How is the installation process for your Cardan Shaft designed to be user-friendly?

A: Our Cardan Shaft is engineered for straightforward installation, allowing for quick setup with minimal downtime. The universal joint design eases alignment and connection, making it suitable for retrofit or new machine setups without complex procedures.Q: What advantages does the high-speed and high-torque capability offer for industrial applications?

A: The shafts capability to handle high speeds up to 6000 RPM and transmit large amounts of torque provides efficient power transmission in demanding industrial machinery, resulting in improved productivity and reduced operational strain.Q: When is maintenance required for these Cardan Shafts?

A: These Cardan Shafts are designed to be largely maintenance-free, thanks to sealed universal joints and robust surface treatments. Regular visual inspection is advised, but routine servicing is significantly minimized compared to conventional shafts.Q: What customization options are available for Cardan Shaft dimensions?

A: We offer a broad range of shaft diameters from 40 mm to 400 mm, with further options for customizing length, width, and overall dimensions according to specific application requirements. OEM designs and bespoke configurations are also supported.Q: Where are these Cardan Shafts most effectively used?

A: Our shafts excel in heavy-duty industrial settings such as rolling mills, paper manufacturing, and textile production machinery, where high-load, high-speed power transmission is crucial.Q: How does the surface treatment enhance shaft durability?

A: Each Cardan Shaft undergoes phosphating and powder coating, providing robust corrosion resistance and extending product lifespan in harsh and moist industrial environments.Q: What are the benefits of choosing a manual, non-computerized Cardan Shaft?

A: Manual, non-computerized Cardan Shafts offer reliability, simplicity, and easy maintenance, reducing the risk of electronic failures and ensuring performance stability in challenging operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Breweries Distillery Machine Spares Category

Bottle Turret Sheet

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard / As required

Weight : Approx. 510 kg

Capacity : Customizable

Material : Stainless Steel

Gripper Pusher Unit

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard/Customizable

Weight : Approximately 7 kg

Capacity : Suitable for MediumtoHeavy Duty Industrial Applications

Material : Highgrade Alloy Steel with Engineered Polymer Parts

Retainer

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Vary as per requirement

Weight : Lightweight

Capacity : Standard

Material : High Grade Steel

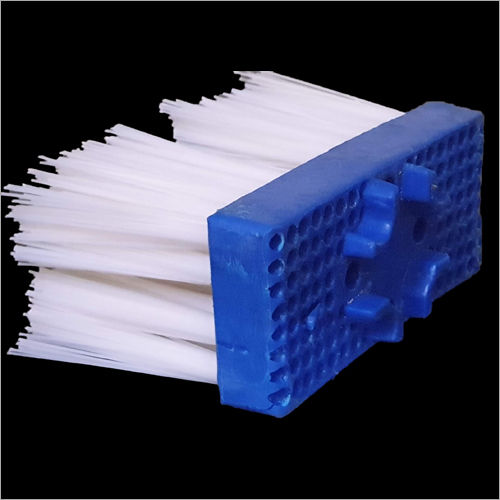

Label Pressing Brush

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Weight : Approx. 100200 gms

Capacity : Manual Operation (Single Label at a Time)

Material : Wooden Base with Nylon Bristles

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free