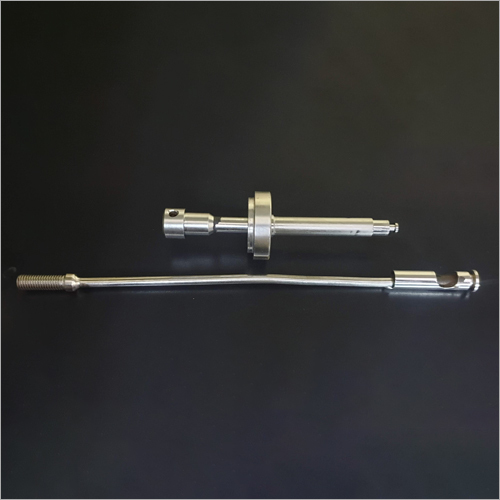

Filling Nozzle

Price 1 INR/ Piece

MOQ : 1 Piece

Filling Nozzle Specification

- Type

- Filling Nozzle

- Material

- Stainless Steel

- Capacity

- Customizable as per requirement

- Computerized

- No

- Automatic Grade

- Manual

- Size

- Standard/Custom sizes available

- Weight

- Approx. 250 grams

- Dimension (L*W*H)

- 12 cm x 2 cm x 2 cm

- Compatibility

- Compatible with standard filling machines

- Suitable For

- Pharmaceutical, Food, Cosmetic, Chemical industries

- Application

- Liquid Filling for bottles, jars, containers

- Finish Type

- Polished

- Leak Proof

- Yes

- Connection Type

- Threaded

- Corrosion Resistance

- Yes

- Cleaning Method

- Easy to Disassemble for Cleaning

- Operating Temperature

- Upto 100°C

- Flow Rate

- Variable as per nozzle size

- Nozzle Diameter

- 3 mm to 14 mm (custom options)

Filling Nozzle Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Filling Nozzle

With state-of-the-art engineering facility and a team of adept professionals, we are dedicated toward presenting the best in grade Filling Nozzle to innumerable clients. The nuzzle has high pressure bearing strength, corrosion resistance, great impact resistance and longer performance as it is fabricated from top-grade stainless steel with modern tools & equipment. Most commonly fitted to liquid fitting apparatus & machines, the Filling Nozzle does not damage by high temperature & high pressure of liquid, and comes in different sizes and grades with first-class packaging.

Precision Filling for Diverse Industries

Our Filling Nozzle caters to a wide range of industries including pharmaceutical, food, cosmetic, and chemical sectors. Its corrosion-resistant stainless steel body and polished finish ensure hygiene and durability, making it suitable for handling diverse liquid products in demanding operational settings.

Customizable for Unique Requirements

With nozzle diameters ranging from 3 mm to 14 mm and adaptable flow rates, this filling solution can be tailored to specific process needs. Whether youre working with small vials or large containers, you can select the most appropriate configuration for your production line.

Hygienic and Easy Maintenance

Designed with user convenience in mind, the nozzle quickly disassembles for thorough cleaning. This feature is crucial for industries enforcing strict sanitary regulations and frequent product changeovers, minimizing downtime and ensuring consistent product quality.

FAQs of Filling Nozzle:

Q: How is this filling nozzle installed on existing filling machines?

A: The filling nozzle features a threaded connection that allows it to be easily attached to compatible standard filling machines. Installation involves securing the nozzle to the machines corresponding threaded port, ensuring a leak-proof fit.Q: What applications is this filling nozzle best suited for?

A: This nozzle is specifically designed for liquid filling in bottles, jars, and containers, making it perfect for pharmaceuticals, food products, cosmetics, and chemicals. Its versatility allows use across manual filling operations in various production settings.Q: When should I choose a custom nozzle diameter or flow rate?

A: Selecting a custom nozzle diameter or flow rate is ideal when you need to handle unique container sizes or specific liquid viscosities. Customization ensures optimal filling accuracy and speed for your particular task.Q: Where can this filling nozzle be sourced from?

A: You can obtain this filling nozzle directly from manufacturers, retailers, suppliers, traders, or wholesalers across India. Custom and bulk orders are available to match specific business needs.Q: What is the cleaning process for this filling nozzle?

A: Cleaning is straightforwardsimply disassemble the nozzle by unscrewing the threaded connection, then wash and sterilize the individual components. This design supports stringent hygiene standards and rapid changeover between products.Q: How does corrosion resistance benefit my operation?

A: Corrosion resistance ensures the nozzle maintains its structural integrity and hygiene, even when exposed to aggressive liquids. This durability reduces replacement costs and maintains product quality over extensive use.Q: What are the advantages of using this manual filling nozzle over automated options?

A: Manual filling nozzles offer precise control, are highly cost-effective, and suit small to medium production runs. Their simplicity allows easy customization, quick maintenance, and adaptability for various product types without complex machinery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Breweries Distillery Machine Spares Category

Gripper Cylinder Part

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Grade Aluminum Alloy

Automatic Grade : Manual

Computerized : No

Type : Gripper Cylinder Part

Crowner Pad - Bottle Seat

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Premium PU Foam

Automatic Grade : Manual

Computerized : No

Type : Crowner Pad Bottle Seat

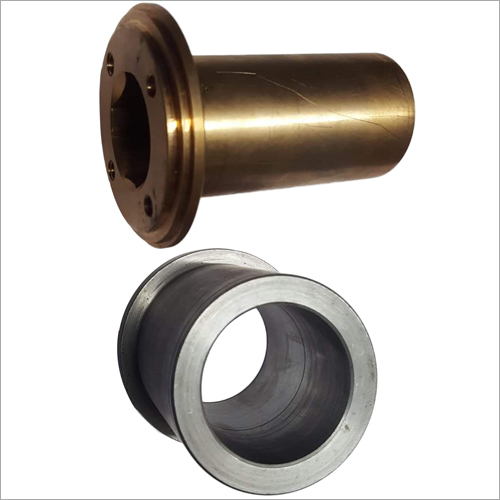

Tulip Center Part

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Brass

Automatic Grade : Manual

Computerized : No

Type : Tulip Center Part

Label Magazine

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Automatic Grade : Automatic

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS