Ledge Plate

Price 1 INR/ Piece

Ledge Plate Specification

- Type

- Ledge Plate

- Material

- High-quality Stainless Steel

- Capacity

- Up to 1000 kg

- Computerized

- No

- Automatic Grade

- Manual

- Cutting Thickness

- Up to 20 mm

- Size

- Standard Custom Sizes Available

- Width

- 200 mm

- Weight

- 5.2 kg

- Dimension (L*W*H)

- 500 mm x 200 mm x 30 mm

- Surface Finish

- Corrosion-Resistant Polished

- Temperature Resistance

- Up to 350°C

- Application

- Industrial Support, Construction, Fabrication

- Standards

- ISO 9001 Certified

- Color

- Metallic Silver

- Installation Method

- Bolt-On/Clamp-On

- Packing Type

- Carton Box

- Edge Type

- Smooth Machined Edge

Ledge Plate Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Ledge Plate

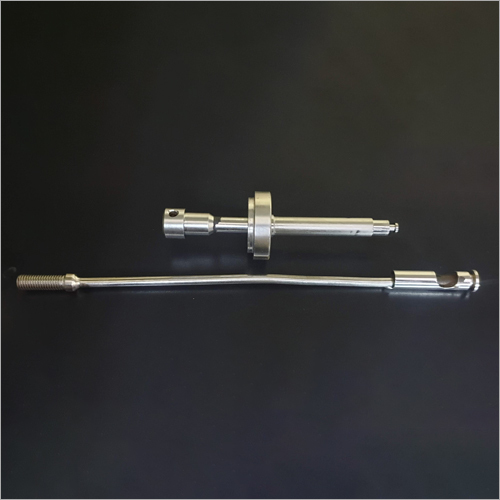

With huge industry knowledge and great support of adept professionals, our organization is committed to proffer the best in grade Ledge Plate to innumerable clients. This type of plate is utilized most widely for preventing the formation of clinkers on the sidewalls and the abrasions because of the moving fuel bed. This is well manufactured from pristine quality material and steel bearings. Easy to fit and longer in performance, the Ledge Plate is provided clients in different sizes, finishes, grades and colors.

Robust Construction for Industrial Reliability

Designed for tough environments, the Ledge Plate supports heavy loads and withstands high temperatures, making it ideal for varied industrial and fabrication needs. Its corrosion-resistant polished surface and precision-machined edges offer enduring performance and enhanced safety for your operation.

Versatile Installation Options

Choose between bolt-on or clamp-on methods to install the Ledge Plate, ensuring quick setup and secure mounting. The plates adaptable design allows for use in both new constructions and retrofit projects, providing flexibility for contractors and engineers alike.

Certified Quality and Custom Sizes

Manufactured in adherence to ISO 9001 standards, each Ledge Plate guarantees reliability and premium quality. Custom sizes and standard dimensions mean you get the precise fit for your specific application requirements, all delivered securely in sturdy carton packaging.

FAQs of Ledge Plate:

Q: How should the Ledge Plate be installed in industrial settings?

A: The Ledge Plate can be installed using either the bolt-on or clamp-on method, depending on your project requirements. Both techniques offer straightforward assembly with manual tools, ensuring a secure and stable fit in support structures.Q: What advantages does the corrosion-resistant polished surface provide?

A: This specialized surface finish enhances durability by protecting the plate against rust and environmental wear, increasing its service life and reducing maintenance frequency, especially in demanding industrial conditions.Q: Where can I use the Ledge Plate within construction or fabrication projects?

A: The Ledge Plate is suited for industrial support, structural frameworks, and fabrication tasks where robust load capacity and temperature resistance are required. It is widely applicable across commercial and manufacturing environments.Q: What is the process for ordering custom-sized Ledge Plates in India?

A: You can contact manufacturers, retailers, suppliers, traders, or wholesalers to request standard or custom sizes. Specify your dimension and thickness requirements, and your order will be processed and shipped in secure carton boxes.Q: When is it beneficial to choose a manual-grade ledge plate instead of an automatic one?

A: Manual-grade ledge plates, like this model, are ideal when precise control and flexibility during installation are prioritized. They require minimal equipment and suit projects where automation is not feasible or necessary.Q: How does the ISO 9001 certification impact product quality?

A: ISO 9001 certification signifies strict adherence to international quality management systems, ensuring consistent product reliability, safety, and performance for every ledge plate manufactured.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Breweries Distillery Machine Spares Category

Bottle Turret Sheet

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Customizable

Computerized : No

Automatic Grade : Manual

Dimension (L*W*H) : Customizable

Filler Lifter Parts

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Custom as per requirement

Computerized : No

Automatic Grade : Manual

Dimension (L*W*H) : As per Drawing / Specification

Tulip Holder - Centring Bell

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Standard

Computerized : No

Automatic Grade : Manual

Dimension (L*W*H) : Varies as per Specification

Filling Nozzle

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Customizable as per requirement

Computerized : No

Automatic Grade : Manual

Dimension (L*W*H) : 12 cm x 2 cm x 2 cm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free