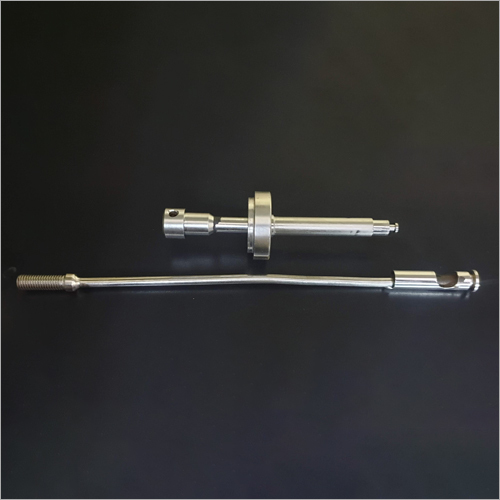

Discharge Guide

Price 1 INR/ Piece

MOQ : 1 Piece

Discharge Guide Specification

- Type

- Discharge Guide

- Material

- High Strength Steel

- Capacity

- Designed for industrial channel flow management

- Computerized

- No

- Automatic Grade

- Manual

- Cutting Thickness

- Up to 25 mm

- Size

- Standard and customizable sizes available

- Width

- Varies as per design

- Weight

- Approx. 45 kg

- Dimension (L*W*H)

- 1200 mm x 400 mm x 250 mm

- Surface Treatment

- Powder coated

- Manufacturing Technique

- Fabricated

- Finish

- Anti-corrosive coated

- Mounting Type

- Bolt-on / flange mount

- Temperature Resistance

- Up to 200°C

- Color

- Grey

- Compatibility

- Fits standard channel discharge systems

- Maintenance

- Low maintenance required

- Shape

- Rectangular

- Usage/Application

- Guiding and controlling discharge flow in industrial systems

Discharge Guide Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Discharge Guide

Assisted by a team of dedicated and ingenious professionals, we are actively engrossed in putting forward A-one Discharge Guide to widely scattered clients. This type of guide is fitted to different models and kind of industrial machines to discharge hot air to various directions. The presented guide is effortless to install as it is precisely designed with needed fastening holes. Made of the finest grade synthetic material with cutting-edge technology, the Discharge Guide does easily not degrade by heat, chemical, & abrasion for a long time.

Reliable Flow Control for Industrial Systems

Engineered to ensure optimal regulation of discharge in industrial channels, this Discharge Guide excels in durability and performance. Its anti-corrosive and powder-coated finish resists wear and tear, even in demanding environments, while the manual settings allow for precise flow adjustments. Designed to fit standard channels, it is an ideal solution for high-capacity discharge flow management in factories, plants, and industrial facilities.

Customizable and Easy to Install

Available in both standard and tailored dimensions, the Discharge Guide adapts seamlessly to specific project requirements. With bolt-on and flange mounting options, installation is straightforward and secure. Each units approximate weight of 45 kg and carefully considered geometry make it manageable during setup, ensuring fast deployment across a variety of industrial settings.

FAQs of Discharge Guide:

Q: How is the Discharge Guide installed in channel discharge systems?

A: The Discharge Guide is designed for bolt-on or flange mounting, making installation straightforward for professionals. It fits standard channel discharge systems, allowing for quick setup without extensive modifications to existing infrastructure.Q: What industrial applications is the Discharge Guide suitable for?

A: This Discharge Guide is ideal for industries requiring precise flow control, such as water treatment plants, manufacturing facilities, and other environments where channelized flow regulation is essential.Q: When should the Discharge Guide be maintained to ensure peak performance?

A: The Discharge Guide requires minimal maintenance, owing to its anti-corrosive powder coating and robust construction. Routine inspections are recommended, but its design significantly reduces the frequency and effort involved in upkeep.Q: Where can the Discharge Guide be used within an industrial facility?

A: It can be installed in any standard channel discharge areaupstream or downstreamwhere controlling direction and volume of flow is necessary, such as in inlet bays or process discharge outlets.Q: What is the process for customizing the Discharge Guides size or specifications?

A: Customization is available to suit unique channel dimensions or requirements. Simply provide your specifications to the manufacturer or supplier; fabrication will be based on those details while adhering to strict quality standards.Q: How does the anti-corrosive coating benefit long-term operation?

A: The powder-coated anti-corrosive finish protects the guide from harsh chemicals and environmental factors, ensuring longevity, reducing maintenance needs, and preventing premature wear even in challenging operational conditions.Q: What are the benefits of using a fabricated, manual Discharge Guide over computerized options?

A: A manual, fabricated Discharge Guide offers simplicity, lower installation and operational costs, and dependable performance without reliance on electronic components, making it ideal for environments where reliability and minimal maintenance are priorities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Breweries Distillery Machine Spares Category

Cardan Shaft

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Computerized : No

Material : Alloy Steel

Dimension (L*W*H) : Custom as per application

Gripper Cylinder Handle

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Computerized : No

Material : Hardened Steel

Dimension (L*W*H) : Approx. 120 x 50 x 45 mm

Filling Nozzle

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Computerized : No

Material : Stainless Steel

Dimension (L*W*H) : 12 cm x 2 cm x 2 cm

Label Magazine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Computerized : No

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free